Food industry

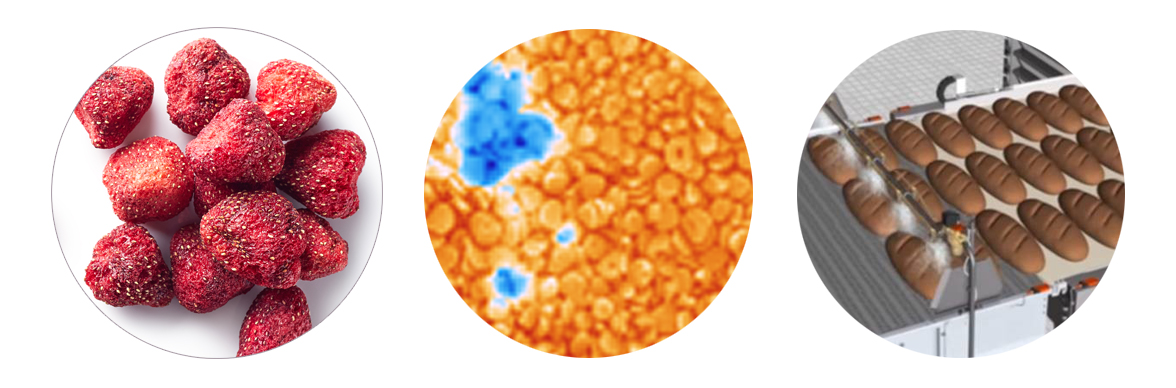

Temperature is an important parameter in many processes in the food industry. Contactless temperature measurement with radiation thermometers (pyrometers) or thermal imaging cameras is often preferable to contact measurement. Temperatures below the freezing point (e.g. in freeze-drying processes) up to a few hundred degrees Celsius (e.g. in baking processes) are important. The spectral range from 8 µm to 14 mm (LWIR) plays an important role because many foods have a high emissivity here.

DIAS Infrared offers numerous suitable devices here, including:

Digital compact pyrometers PYROSPOT with IP65 stainless steel housing

- DT 25L: -20 °C to 700 °C (output 4 to 20 mA and interface for parameterization)

- DT 40L: -40 °C to 1000 °C (output 4 to 20 mA and USB interface)

- DT 42L: -40 °C to 1000 °C (output 4 to 20 mA and emissivity adjuster)

- DT 44L: -40 °C to 1000 °C (output 0/4 to 20 mA and RS-485 interface)

- DT 47L: -40 °C to 1000 °C (output 0/4 to 20 mA and Ethernet interface)

Infrared camera PYROVIEW with IP54 compact housing or IP65 stainless steel housing

- PYROVIEW 380L: -20 °C to 120 °C, 50 °C to 500 °C (384×288 pixels, Ethernet interface/real-time 50 Hz)

- PYROVIEW 640L: -20 °C to 120 °C, 50 °C to 500 °C (640×480 pixels, Ethernet-interface/real-time 50 Hz)

Process monitoring in industrial bakeries

A system solution with stationary thermal imaging cameras PYROVIEW was developed especially for process monitoring in large bakeries.

The problem

Automation in industrial bakeries means increased productivity through savings in time and personnel. At the same time, automation makes physically demanding work easier. The decisive factor for success is consistent product quality of the baked goods.

In a industrial bakery, the dough pieces are no longer portioned, shaped and pushed into and out of the oven by hand. Today, this is largely done by robots. It can happen that baked goods or parts of them remain in the continuous oven and go through several baking cycles. If these parts are then transported out of the oven on the conveyor belt, they are not only burned, but due to the excessive temperature they can also burn, anneal strongly or outgas and damage the conveyor belts in the process.

The solution

In order to minimize this risk, the use of stationary thermal imaging cameras PYROVIEW for non-contact temperature measurement together with special software makes economic sense. The cameras detect impermissibly high temperatures so that damaged baked goods can be recognized in good time, sorted out and, if necessary, deleted.

The system

The system for large bakeries consists of the thermal imaging camera PYROVIEW 380L/640L protection in an IP65 stainless steel housing, a control box with touch PC and PLC and all necessary accessories (e.g. cables, brackets) – but it can be completely customized or extended. The PYROSOFT FDS software runs on the touch PC mounted in the control box and visualizes the status of the system. Alarm data including all video streams are recorded, stored and can be used for tracking and evaluation.

The PYROVIEW thermal imaging camera uses hotspot detection to detect whether a hazard is present or not and forwards an alarm signal to the PLC. The threshold values for the hotspots can be individually set and programmed. The system can thus also be adapted to different grades and batches. A traffic light system (red/green) and an additional signal horn indicate the current system status so that the machine operator or other personnel can intervene quickly if necessary. In addition, the temperatures of the baked goods can be monitored directly. Temperature deviations are directly transmitted to the PLC of the baking oven. An existing spray device can also be coupled to the system’s PLC. In the event of an alarm, the water flow of the device is increased so that burning or excessively hot baked goods are immediately extinguished.

System components (individually configurable)

- Thermal imaging camera PYROVIEW 380L/640L

| Device type | Measuring temperature range | Spectral range | Sensor | Resolution | Interface | Optics |

|---|---|---|---|---|---|---|

| PYROVIEW 380L protection" | –20 °C to 120 °C, 50 °C to 500 °C | 8 µm to 14 µm | micro bolometer array | 384 x 288 pixels | Ethernet (real-time, 50 Hz) | with motor focus |

| PYROVIEW 640L protection" | –20 °C to 120 °C, 50 °C to 500 °C | 8 µm to 14 µm | micro bolometer array | 640 x 480 pixels | Ethernet (real-time, 50 Hz) | with motor focus |

- Control box with touch computer, software PYROSOFT and SPS

- Customer support, like

✅ individual planning and realization,

✅ commissioning on site and instruction of personnel,

✅ system maintance

Application note

Please read our application note about “Process monitoring in industrial bakeries”.

Contact

Do you have any questions regarding our thermal imaging cameras PYROVIEW or any other request?

We will be happy to advise you without obligation:

📩 Email: sales@dias-infrared.de

📞 Phone: +49 351 896 74 10