Thermal inspection with stationary fixed infrared cameras PYROVIEW and thermal imaging software PYROSOFT

The task

In order to be able to carry out a thermal „all-round“ inspection, the measurement objects must be detected from all sides. This usually requires several thermal imaging cameras. In the case of round objects such as pipes or round containers, three cameras are usually sufficient, each installed and arranged offset by 120°. For square objects, on the other hand, at least four thermal imaging cameras are required. If monitoring of the front and back is required, two thermal imaging cameras are often sufficient. If the measurement objects are very large, such as a blast furnace, up to eight cameras may be required for the entire surface.

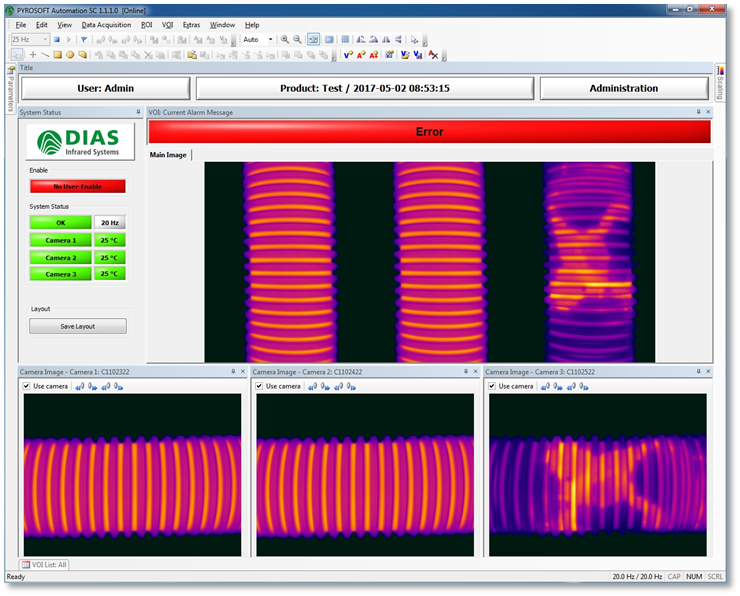

Each camera delivers individual images that must be analyzed in real time. The overall picture only emerges when the individual files are all viewed together. This effort can be reduced if all data are merged into one image. Therefore, a software is needed that combines all camera images and evaluates them in real time. The result of this evaluation should also be as easy as possible to connect to the plant PLC. A process control or the ejection of detected faulty parts can then be easily realized.

The solution

This thermal all-round view is provided by the PYROSOFT AutomationSC software developed by DIAS. The „SC“ stands for „Synchronized Cameras“. The thermography software generates a common data stream from two to eight cameras, whereby the arrangement of the individual cameras in the overall image can be selected. In real time, all data from up to eight cameras are thus acquired and evaluated synchronously. This creates a uniform thermal image for ROI and VOI calculations. This data can be recorded permanently as an infrared film or in a ring buffer. Also, to save memory space, only alarm images can be stored.

💡 The big advantage of AutomationSC is that you do not have to evaluate individual files for hot spots, for example, but only one. This makes your documentation much easier.

Examples

Condition monitoring of transport ladles with 3 IR cameras

🔎 Checking the brick lining (hotspot search)

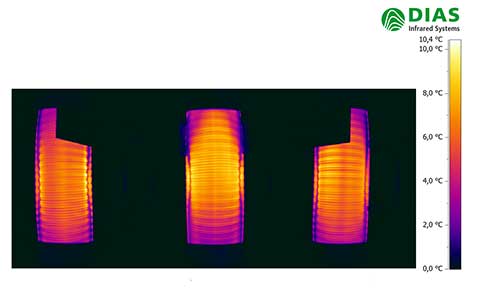

Control of uniform pipe heating with 3 IR cameras

🔎 Avoiding bending errors

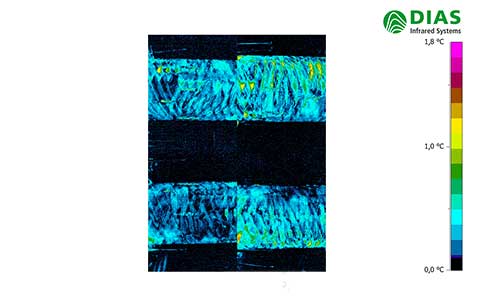

Control of pipes with 4 IR cameras

🔎Checking the fine wires inside the tubes

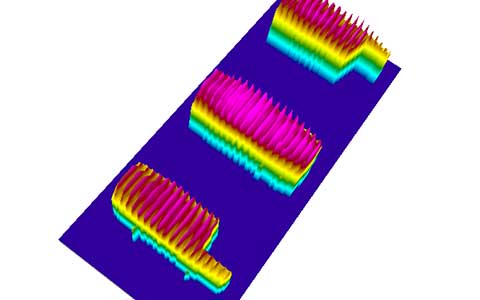

Control of pipe heating with 3 IR cameras

🔎3D display helps especially with hotspot detection

The PYROSOFT AutomationSC software also supports you optimally in image evaluation. First of all, the important image areas (Region Of Interest = ROI) can be defined. Points, lines, rectangles, circles/ellipses and polygons are available for this purpose. Depending on the type, different values are automatically calculated for these ROIs. Beside the classical values Min, Max, Avg there are also the respective image coordinates (x,y) as well as lengths and widths are available. From these values you now agree on your VOIs (Value Of Interest = VOI) which can also be linked arithmetically.

Every single VOI value can then be sent to your PLC and/or immediately trigger an alarm condition by means of a limit value.

There are also more complex functions like histogram, trend, FFT, filter images, reference and difference images.

Define alarms with fixed or variable thresholds and alarm associations to immediately detect critical temperatures and display, store and log them offline and online. Using the configurable IO system, triggers and reference values can be read in from the process controller. Measured values and alarm states can be output to the process controller. The connection can be made via PROFIBUS, PROFINET, WAGO module, Modbus, OPC, TCP socket or text file.

With PYROSOFT AutomationSC you connect your PYROVIEW thermal imaging cameras to your process. A direct coupling to your PLC is easy to realize with it. Our technical sales department with years of experience will be happy to clarify your questions about system configuration or image evaluation and will provide you with optimal support for the solution.

Further information

More information and technical details can be found in our application note.