Research and development

Non-contact temperature measurement gives you the ability to measure and analyse temperature distributions and profiles of many different materials and components in the R & D process.

Non-contact temperature measurement in high magnetic fields for the research of solid matter

Infrared temperature measurements in high magnetic fields were not possible for technical reasons until now. The infrared camera PYROVIEW 640L-PMF is the world’s first IR camera that can measure precisely without contact in permanent magnetic fields of several Tesla. In this way technical studies on semiconductors, magnetization measurements, nuclear resonance studies, research work in cell biology as well as the determination of critical parameters of high field and high temperature super conductors can be made for example.

The solution is: Non-contact temperature measurement with the infrared camera PYROVIEW 640L-PMF in high magnetic fields

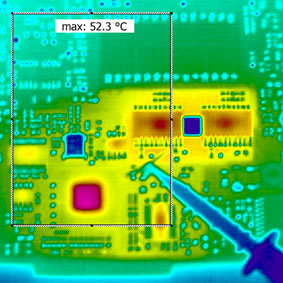

Printed circuit board testing

During construction process as well as during manufacturing of circuit boards, infrared cameras can be used to visualize thermal behaviour of single component parts. This allows faulty modules to be detected and thermal optimazation to be implemented.

The solution is: Infrared cameras PYROVIEW for printed circuit board testing

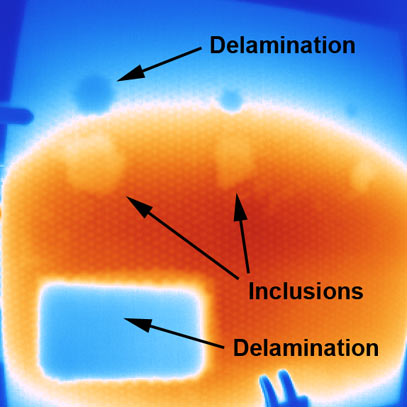

Non-destructive testing of materials using an IR camera – Active thermography

Hair-line cracks, air inclusions and other manufacturing errors can hardly be detected reliably visual, magnetic or electrodynamic detected in composite materials. The challange are non-destructive testing methods for specifically larger areas.

The solution is: Non-destructive testing of materials using active thermography

Combustion of biomasses – Non-contact temperature measurement in combustion chambers

The stock of fossil fuels like mineral oil, natural gasonline and carbon is constantly dimishing. At the same time their use causes an increased emission of carbon oxide into the atmosphere. Regional available fuel resources for enegery supply are a good alternative but their combustion conditions and their emission decrease have to be controlled.

The solution is: Use of an infrared camera in a model combustor for analysis and evaluation of firing technological properties of variable, biogenic fuels

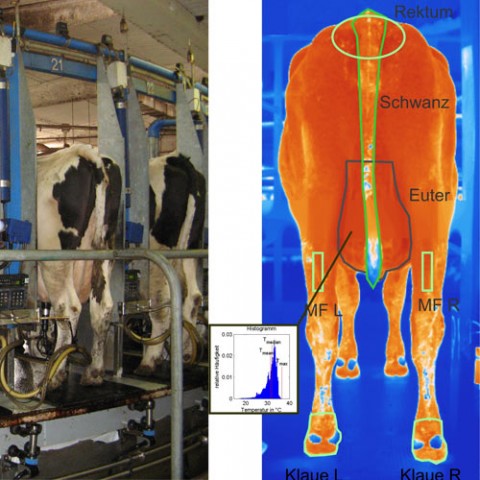

Thermography in veterinary medicine

The challange:Within the framework of a R&D project “VIONA” (“Veterinary Infrared Orientated online Analysis system”) the body temperature rise of animals as an important indicator for the diagnostics of diseases has been studied. It becomes apparent using the example of a milk cow flock with 500 animals that a conventional manual fever measurement would be very costly. This task poses also a challenge to the thermography though the

measurement certainty of the absolute temperature has to be improved of one order magnitude compared to the conventional infrared cameras.

The solution is: Thermography research with infrared cameras PYROVIEW in veterinary medicine

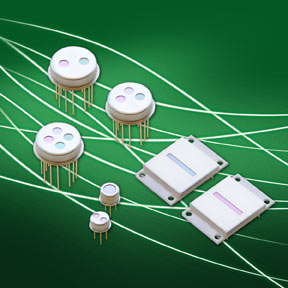

IR sensors for spectroscopy and gas analysis

For the special requirements of the gas analysis in industrial, environmental and medical technology, pyroelectric sensors with up to four independent spectral channels were developed. In the development of compact spectrometers in the mid-IR region pyroelectric arrays in combination with linear variable filters (LVFS) are advantageous usable, because new and very low priced solutions are possible.

The solution is: Infrared detectors and arrays PYROSENS