PYROVIEW Thermal imaging cameras – Thermography for industry, research & inspection

PYROVIEW Thermal imaging cameras - Thermography for industry, research & inspection

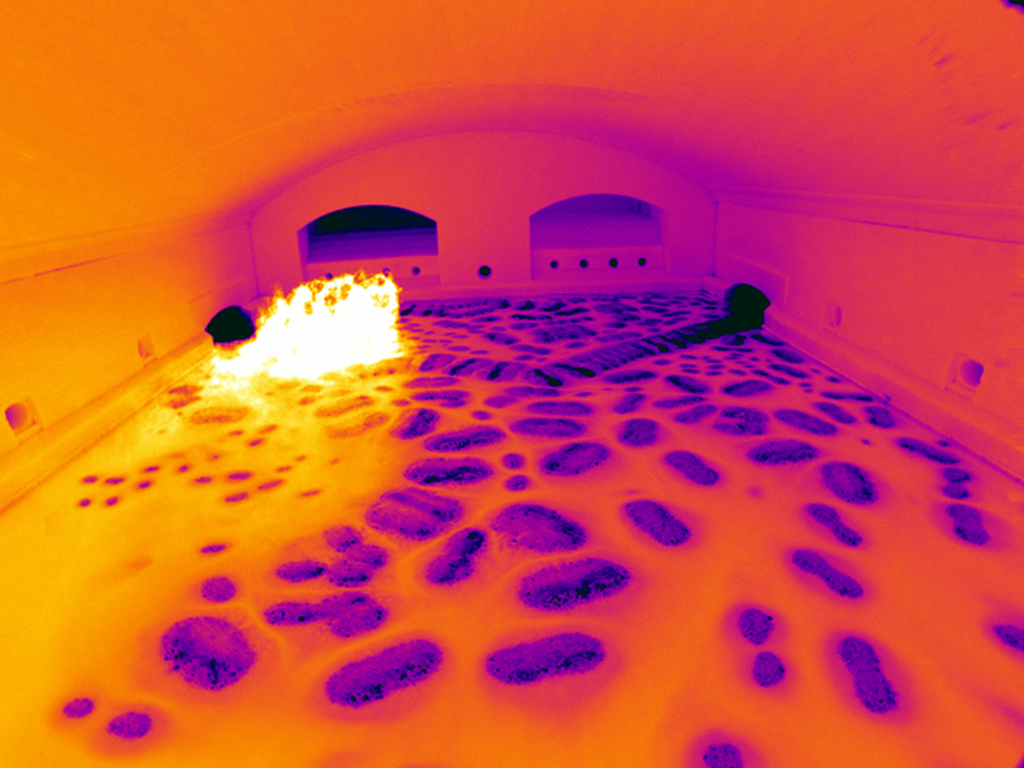

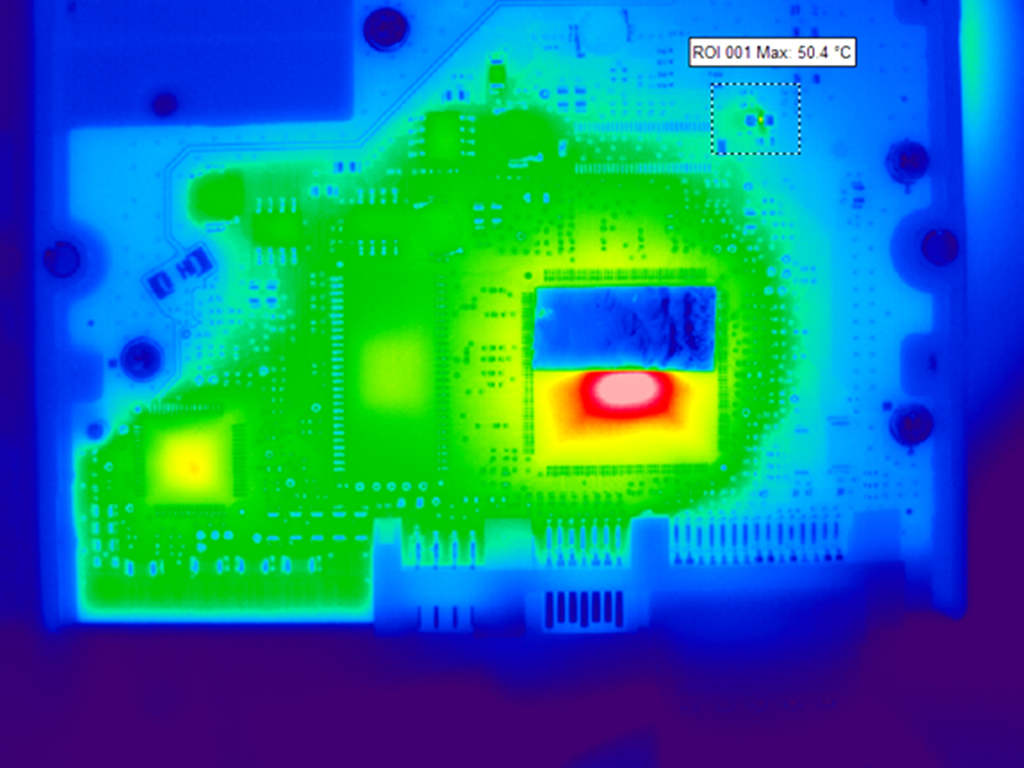

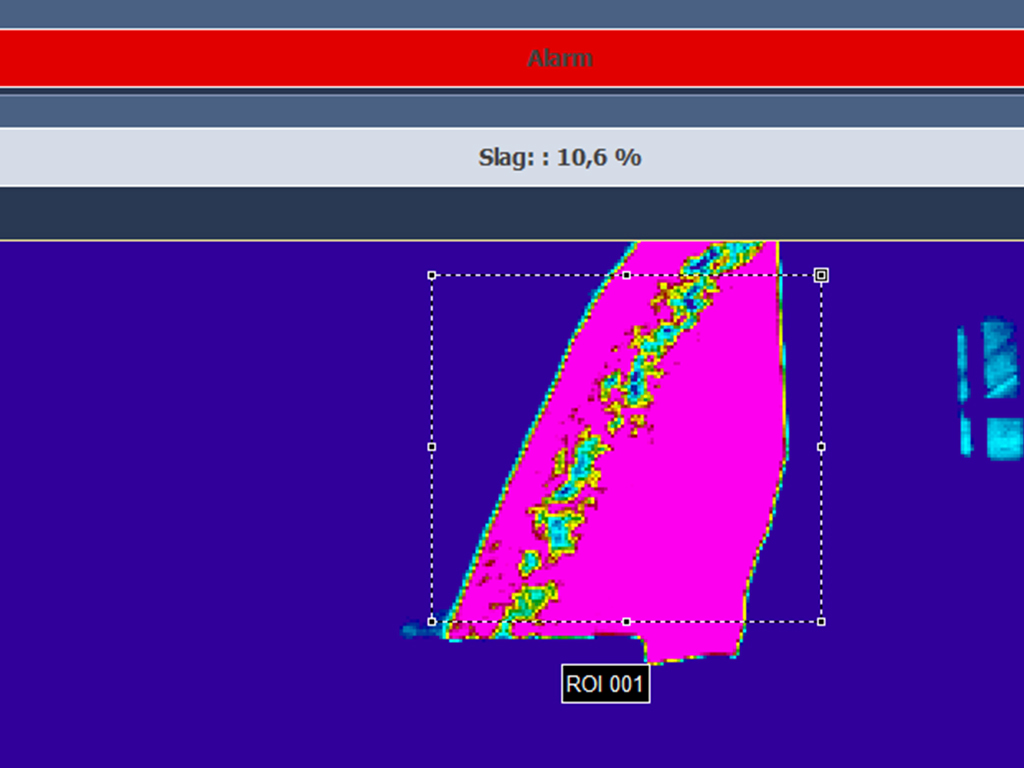

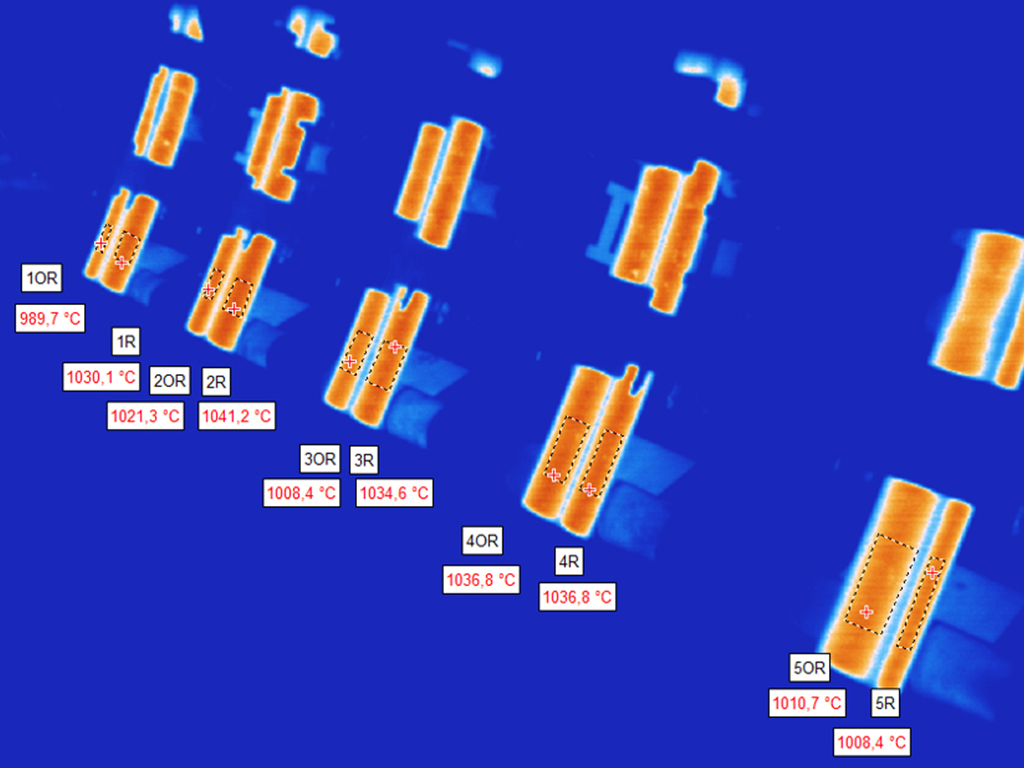

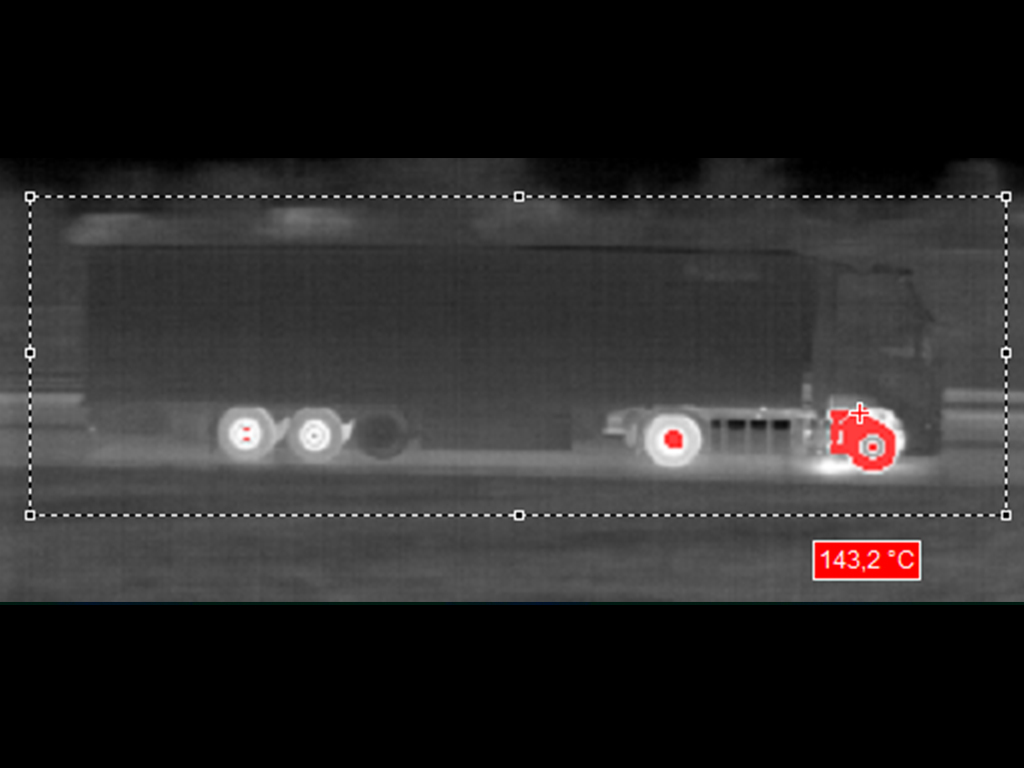

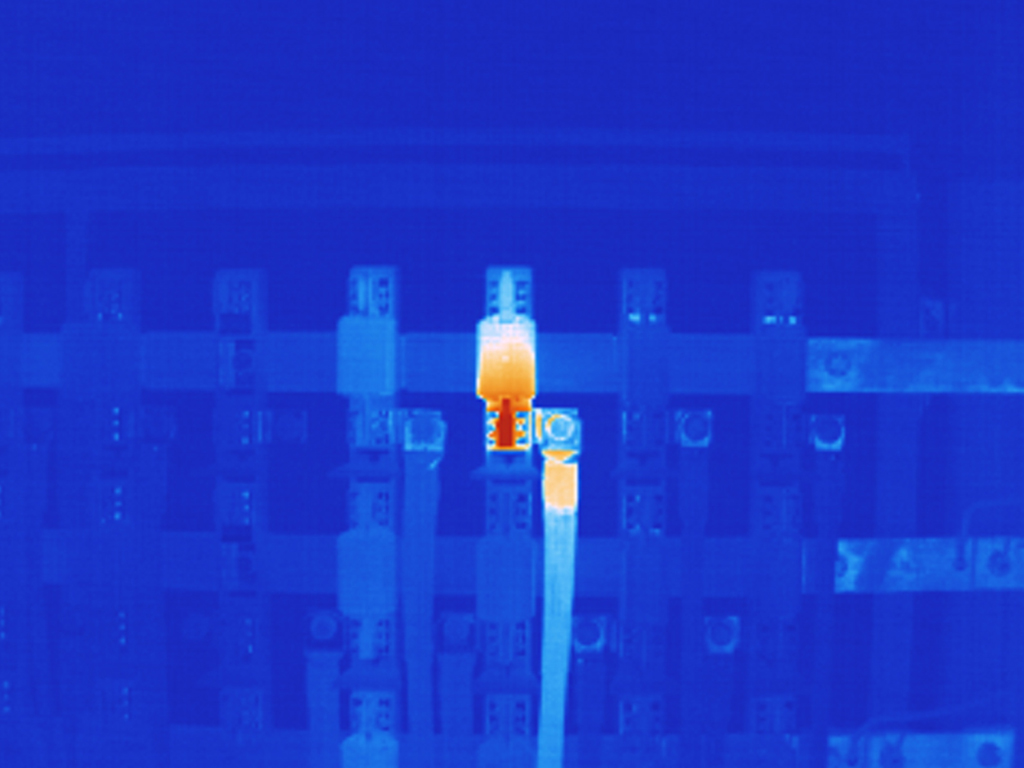

Our thermal imaging cameras in the PYROVIEW series provide precise thermographic data for demanding industrial applications, fire protection systems and research projects. Whether stationary monitoring or integration into automated processes – with infrared resolutions of up to 1920×1080 pixels, our cameras offer reliable real-time temperature measurements.

Advantages of PYROVIEW thermal imaging cameras

Our in-house developed IR cameras offer numerous advantages:

Model overview IR cameras PYROVIEW

| Camera type | Pixels | Temperature range | Spectral range | Application |

|---|---|---|---|---|

| PYROVIEW 380L | 384 x 288 | -20 °C to 500 °C | LWIR | Early fire detection, process monitoring, R & D |

| PYROVIEW 640L | 640 x 480 | -20 °C to 500 °C | LWIR | Quality control, process monitoring, R & D |

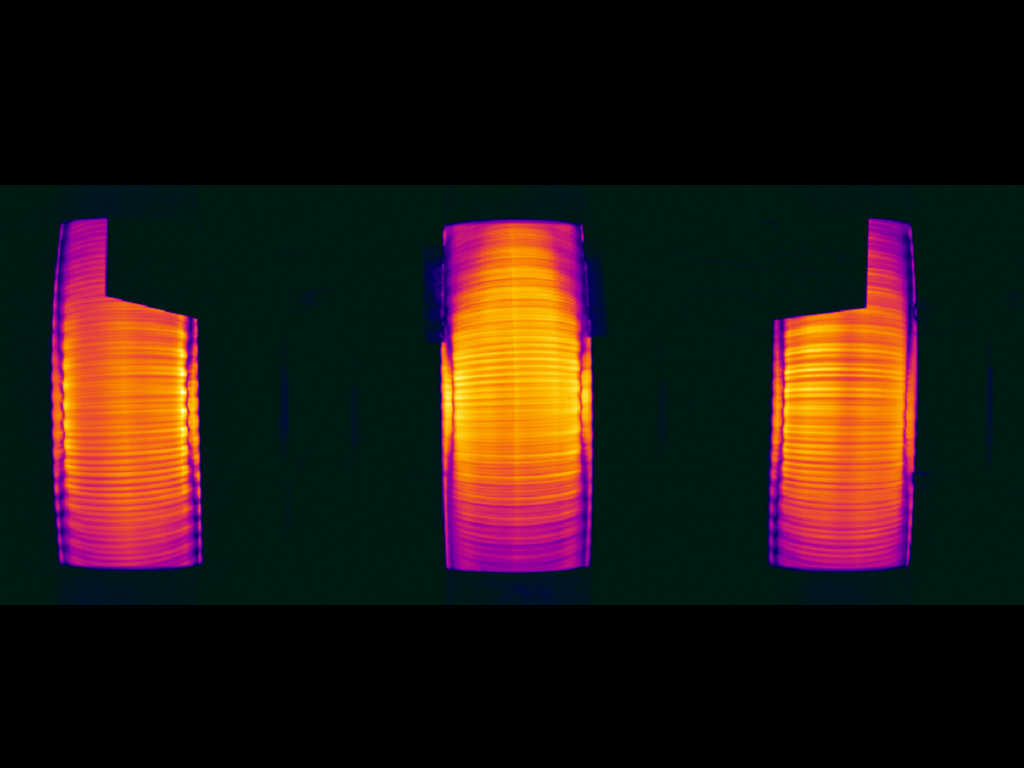

| PYROVIEW 640M | 640 x 480 | 200 °C to 500 °C | MWIR | Metal and ceramics industry |

| PYROVIEW 640G | 640 x 480 | 300 °C to 700 °C | MWIR | Glass industry |

| PYROVIEW 640F | 640 x 480 | 600 °C to 1250 °C | MWIR | Measurement through flames and gases |

| PYROVIEW 512S | 512 x 408 | 300°C to 1200 °C | SWIR | Metal and ceramics industry |

| PYROVIEW 512N | 512 x 384 | 600 °C to 3000 °C | NIR | Metal industry |

| PYROVIEW 768N | 768 x 576 | 600 °C to 3000 °C | NIR | Metal industry |

| PYROVIEW 1600N | 1600 x 1200 | 650 °C to 1800 °C | NIR | Metal industry |

| PYROVIEW 1920N | 1920 x 1080 | 650 °C to 1800 °C | NIR | Metal industry |

Our PYROVIEW IR camera models at a glance

Models PYROVIEW compact+

Models PYROVIEW protection

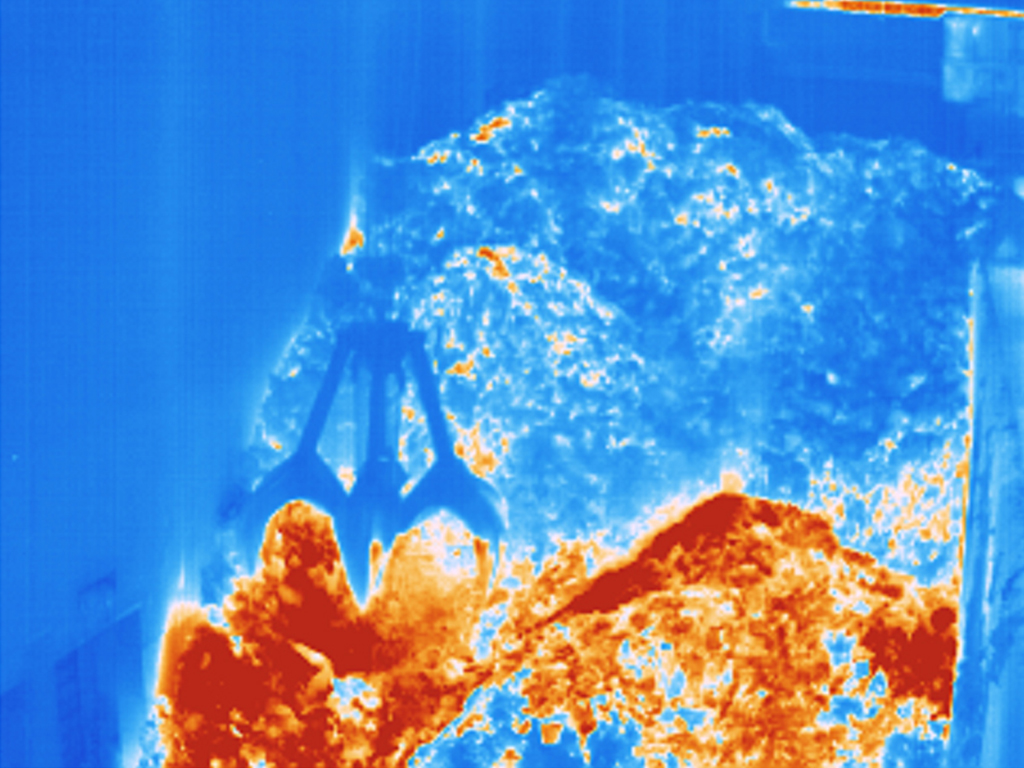

Typical areas of application

of our infrared cameras PYROVIEW

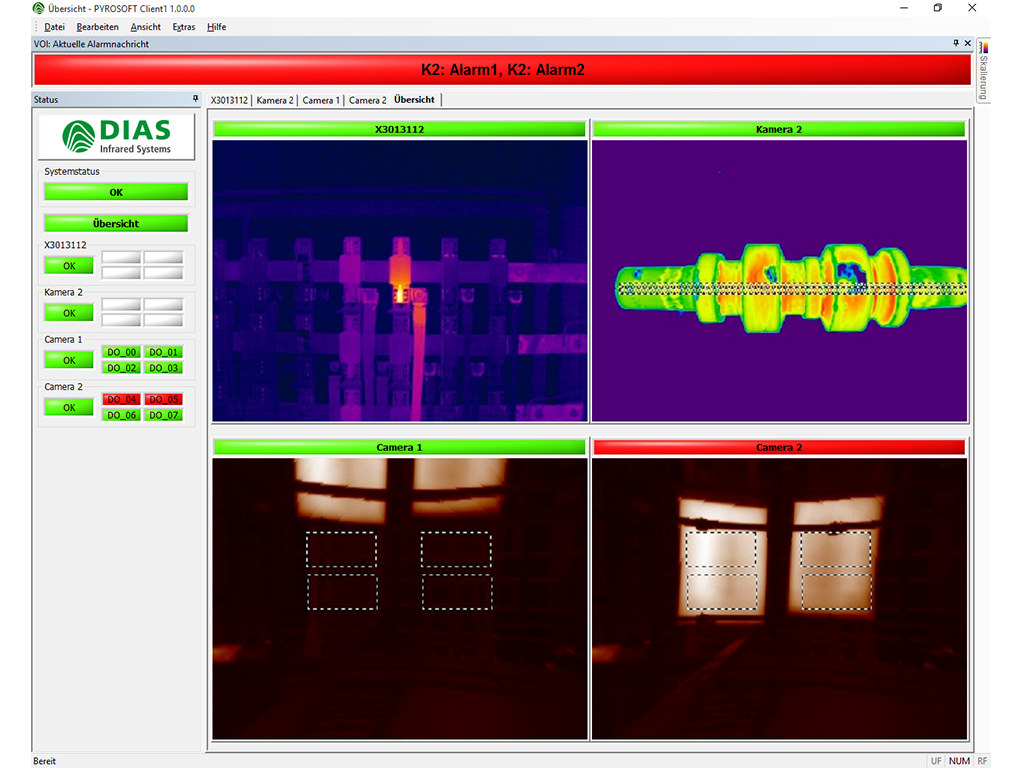

Software & Interfaces

DIAS’ own “PYROSOFT” software enables fully automatic control, data acquisition and evaluation. PYROSOFT enables the input/output of analog/digital values via the IO system, direct bidirectional connections to the PLC via LAN (PROFIBUS, PROFINET, WAGO, Modbus, OPC, TCP socket, text file).

📩 Request a project or fill out the questionnaire now!

Start questionnaire

Do you already know which application you are planning? Then our structured questionnaire will help you to systematically record all the important requirements for your thermal imaging camera.

Zur Seite

Open contact

Would you like to speak directly to the right expert or quickly leave your details? Our overview shows you how.

Zur Seite

Image credits: DIAS Infrared GmbH, Shutterstock.de/david-tadevosian, Katrin Schindler (Von Herzen Fotografie)