Continuous casting temperature measurement with infrared camera PYROVIEW

High temperatures are mostly coupled to a high energy input. The quality of the final goods quite often depends on the temperature

control.

The product quality as well as the energy demand can be deciding affected with the appropriate measurement devices. The measurement system amortizes very fast in many cases, so that a better quality is achieved with a less energy input.

Typical applications can be found for instance in the steel industry. A mostly rectangular strand profile is formed out of liquid steel with a mold. Afterwards, the strand profile has to be cooled down in several levels.

The process temperature is an important quality factor in the production of steelg

Depending on the size of the factory there can be several strands too. The optimal coolingdown of the strands can be controled with several water nozzles in several zones.

Also the writing speed (e.g. 2-3 m/s) affects the cooling down and of course directly the efficiency of the factory. After the steel strand has left the cooling zone, it is completely set.Afterwards it gets usually cut with the help of blowpipes into the desired lengths.

The optimal material properties are only achieved when all process parameters are right in the casting process and the steel is set in a homogeneous alloy structure. It can get particulary expensive if quality defects are recognized later in the further processing. Typical examples are steel wire for car tires or steering components for trucks as well as other safety components which must have an increased economic life-time. If the process temperature is too high, the material structure is seriously affected. If the process temperature is too low, cracks can be formed quickly when straightenig the strands. The most important process parameter for the optimal control is thereby the temperature measurement on the outflow zone of the strand if a high surface quality and a crack-free internal structure are required.

Because the typical temperature are in the range between 800 °C and 1000 °C and the measurement object is moving, optical temperature detectors are used. Conventional

pyrometers have proven particulary useful that detect infrared radiation preferably short-wave and calculate out of it the surface temperature of the steel. Devices that measure long-wave (8 µm to 14 µm) are less usefull because the steel surface oxidates when cooling and thereby the radiation characteristics change intensly in the range from 8 µm to 14 µm and secondly because the water vapor disturbs in this wavelength range.

The traditionally used pyrometers measure though only one point on the strand or one line if a IR scanner or a pan-pyrometer is plugged. Only one side of the strand is reached with it. Because all sides of the strand should be cooled all-over, the detection of the entire surface (top, bottom, left side, right side) should be aspired.

The infrared camera PYROVIEW measures temperature contactlessly on several sides of the steel strand

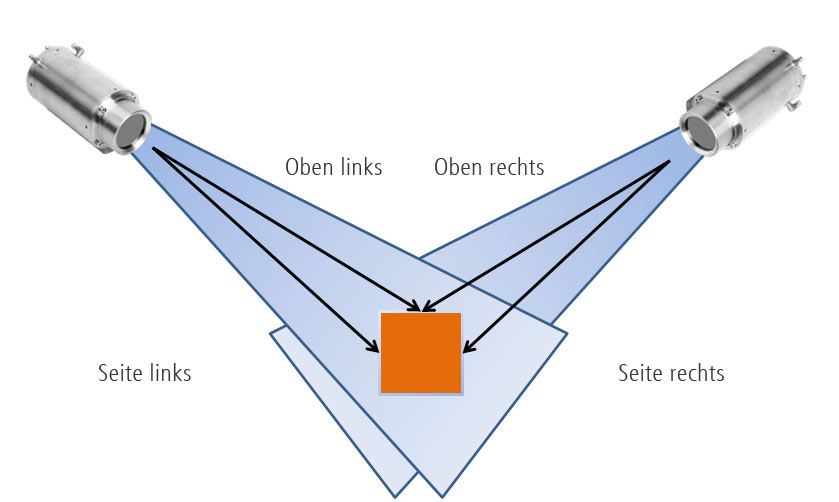

That can be realized best with minimum two infrared cameras PYROVIEW 512N that measure from the left side and right side one strand or several strands. In this way, three temperatures of the steel strand can be generated (left side, right side, 2× top side – is seen by both cameras).

If the bottom side should be measured too, a third camera is necessary. However, a suitable mounting position is not available in mostly factories. An easy validation of the measurement values is possible because the top side of the strand is detected by both cameras. In addition you get a certain redundancy

The infrared camera PYROVIEW 512N provides thermal images with a high resolution of 512 × 384 pixels and allows

a more flexible temperature data acquisition on the entire strand output, independent from the particular geometry that is produced.

The powerful online software PYROSOFT allows the easy definition of the particular measurement zones on the compute

The camera can be used for process monitoring as well as for R & D tasks (IR video recording for later detailed analysis, testing of other steel qualities, change of parameters, data evaluation via mathematical composition, and so on).

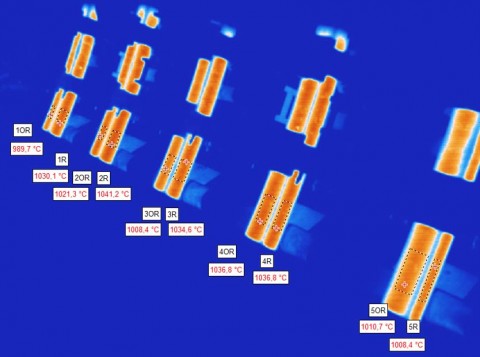

Thermal images with high resolution and hotspot temperature display

Because of the high geometrical resolution of 512 × 384 pixels, temperatures can be detected very well even from great distances. The influence of the measurement by tinder is improved substantially in contrast to a point-shaped evaluation (pyrometer), because minimum nonscaled positions are enough for the temperature detection (maximum value evaluation). Special evaluation functions allow an automatic display of the hotspot temperature that is specifically importontant for the process control.

Saving costs with thermal imaging system

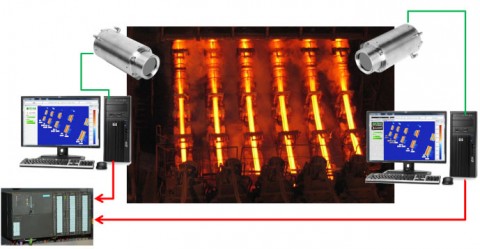

Depending on customer demands the thermography system can work autonomically as a support for the factory operator in the control panel or it can be connected directly to the programmable controller (SPS). The automatic control increases not only the product quality but also possibly reduces personnel costs because one operator can supervise several factories. The temperature measurement data and the camera image can be notified to the operator on a screen and are displayed in trend charts. In addition, all relevant data can be tied to the custom-quality system to enable a long-term recording and documentation.

Technical data infrared camera PYROVIEW

| Device type | IR camera PYROVIEW 512N compact+ | IR camera PYROVIEW 512N protection |

|---|---|---|

| Spectral range | 0,8µm to 1,1 µm | |

| Temperature range | 600 °C to 1500 °C (one continuous measurement range), optional 1400 °C to 3000 °C | |

| NETD1 | < 1 K (600 °C, 60 Hz) | |

| Field of view (HFOV x VFOV) | 36° x 27°, optional: 51° x 40°, 26° x 19°, 19° x 14°, 13° x 9°, 9° x 7°, borescope lens 71° x 56° (for combustion chambers: IR camera PYROINC 512N) | |

| Motor focus | yes | |

| IR sensor | high dynamic 2D-Si-CMOS-Array (512 x 384 pixels) | |

| Measurement uncertainty1 | 1 % of measured value in °C | |

| Measurement frequency | internal 60 Hz, selectable: 60 Hz, 30 Hz, 15 Hz,… | |

| Response time | internal 33 ms, selectable: 2/measurement frequency | |

| Interface | Gigabit-Ethernet (real-time, 60 Hz), galvanically isolated digital inputs (trigger) and digital outputs (alarm) | |

| GigETM vision | ja | |

| Connectors | round plug connector HR10A (12 pin, power supply, digital inputs and outputs), round plug connector M12A (Ethernet) | round plug connector M23 (16 pin, power supply, digital inputs and outputs), round plug connector M12A (Ethernet) |

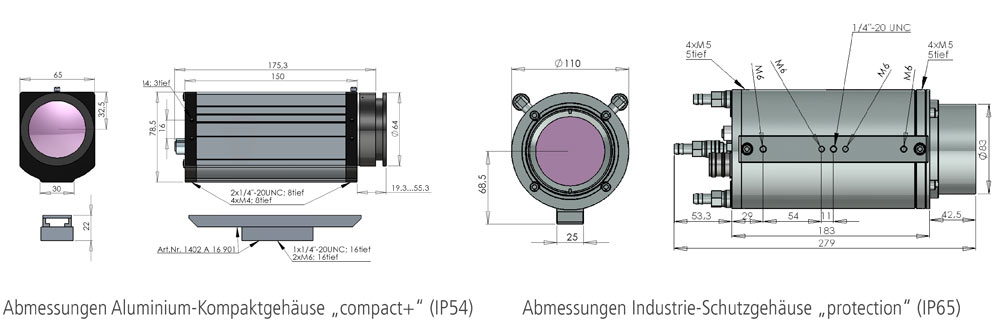

| Housing | aluminium compact housing IP54, 65 mm (L) × 160 mm (W) × 79 mm (H), without lens and connectors, optional with weather protection housing with pan-tilt-unit | industry protection housing IP65, stainless steel, with air purge and water cooling, diameter 110 mm, length 280 mm (without mechanical mounting and connectors), 6 bar max. water pressure, 2 bar max. air pressure, protection window |

| Weight | ca. 1,6 kg | ca. 4,2 kg |

| Operation temperature of camera | –10 °C to 50 °C | –10 °C to 50 °C (without water cooling) –25 °C bis 150 °C (with water cooling) |

| Power supply | 12 V to 36 V DC, typical 10 VA | |

| Storage onditions | –20 °C to 70 °C, max. 95 % rel. humidity | |

| Software | control and imaging software PYROSOFT for Windows(R), customized modifications on request | |

| Scope of delivery | infrared camera PYROVIEW 512N, calibration certificate, manual, software PYROSOFT Compact | |

| (1)Further technicals specs can be found here: Datasheet infrared camera PYROVIEW 512N | ||

An overview of the non-contact temperature measurement on casting with the infrared camera PYROVIEW see this PDF:

Quality assurance in continuous casting plants – with stationary infrared cameras PYROVIEW