Reinforcing steel - Non-contact temperature measurement in steel mills

For the production of reinforced concrete reinforcing bars made of steel are used to make the concrete resistant of occurrent drag and compressive forces. Scrap metal is being melted for the production of reinforcing bars and is casted in continuous casting to steel billets.

The steel billets are then rolled and stretched . In this form they are continued processing in other industries. In order that the reinforcing steel has the appropriate strength and does not get brittle it is important that a certain temperature band is not fell below or gets exceeded.

An infrared line camera PYROLINE 128M with a special spectral range from 3 µm to 5 µm is in a temperature range from 400 °C to 1200°C is used to detect this. The camera with a IP65 protected industry housing was equipped with an additional air purge to keep the lense free of dust and dirt. A bridge over the band conveyor was chosen as a location for installation. So the access to the camera in a case of maintenance is guaranteed.

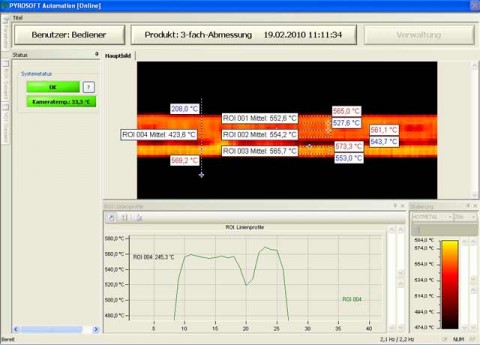

The data is sent via fibre optics to a computer in the control room to fulfill the hard electromagnetic requirements. The computer with the software PYROSOFT Automation records continuously a thermographic picture of the passing steel billets. The picture is played on a screen in the control room and is available for the user immediately. In addition there is a data storage to make the pictures available for quality control at a later date.

Because different sizes and amounts of collateral legs of reinforcing bars are produced, the software allows the switching of saved templates per touch-screen. In this way it is guaranteed that the right settings are used.

All information at a glance

Quality Control in Steel Mills with DIAS Infrared Line Cameras

PYROLINE

Related links

Overview of all infrared line cameras PYROLINE